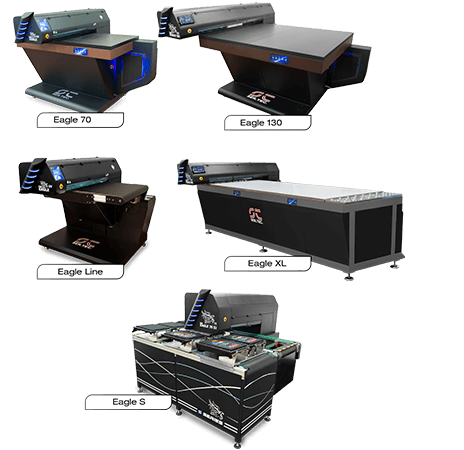

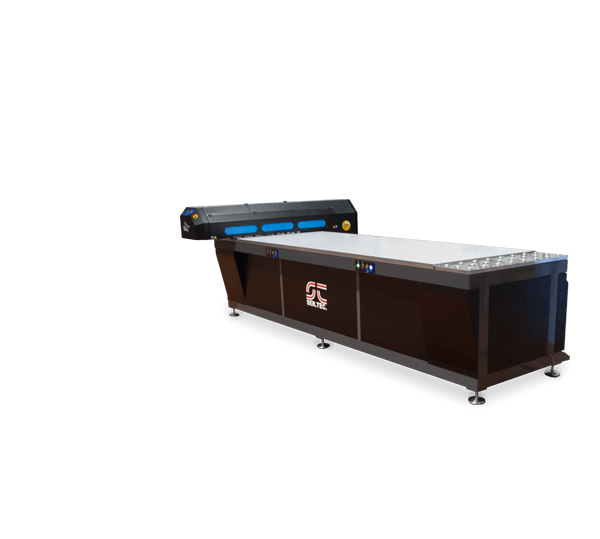

The Eagle printers has been specifically developed for industrial applications. Internal mechanics and firmware are designed for maximum performance and reliability. Eagle printers are equipped with the latest technology to give high quality prints with defined details and sharp colors.

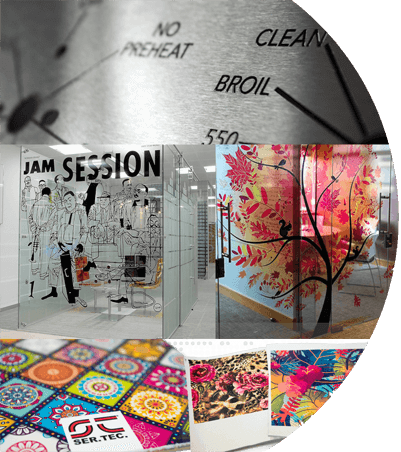

Thanks to the variety of inks and configurations there is no limit to the applications achievable with the Eagle.

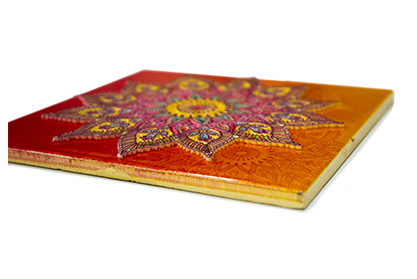

UV inks

Thanks to UV Led technology that don’t need heat to cure the print is possible to print even on heat sensible materials:

wood, plastic, ceramic, paper, metals and much more.

colored or transparent materials using white ink.

color-white-color for two-faced images on glass or other transparent materials.

Cylindrical objects with the optional round object kit

3D or braille effects

Rigid and flexible materials

Hybrid inks

Hybrid inks ensure optimum seal and high quality prints for industrial applications on materials like:

Ceramic

Metals

Leather

Glass

other materials

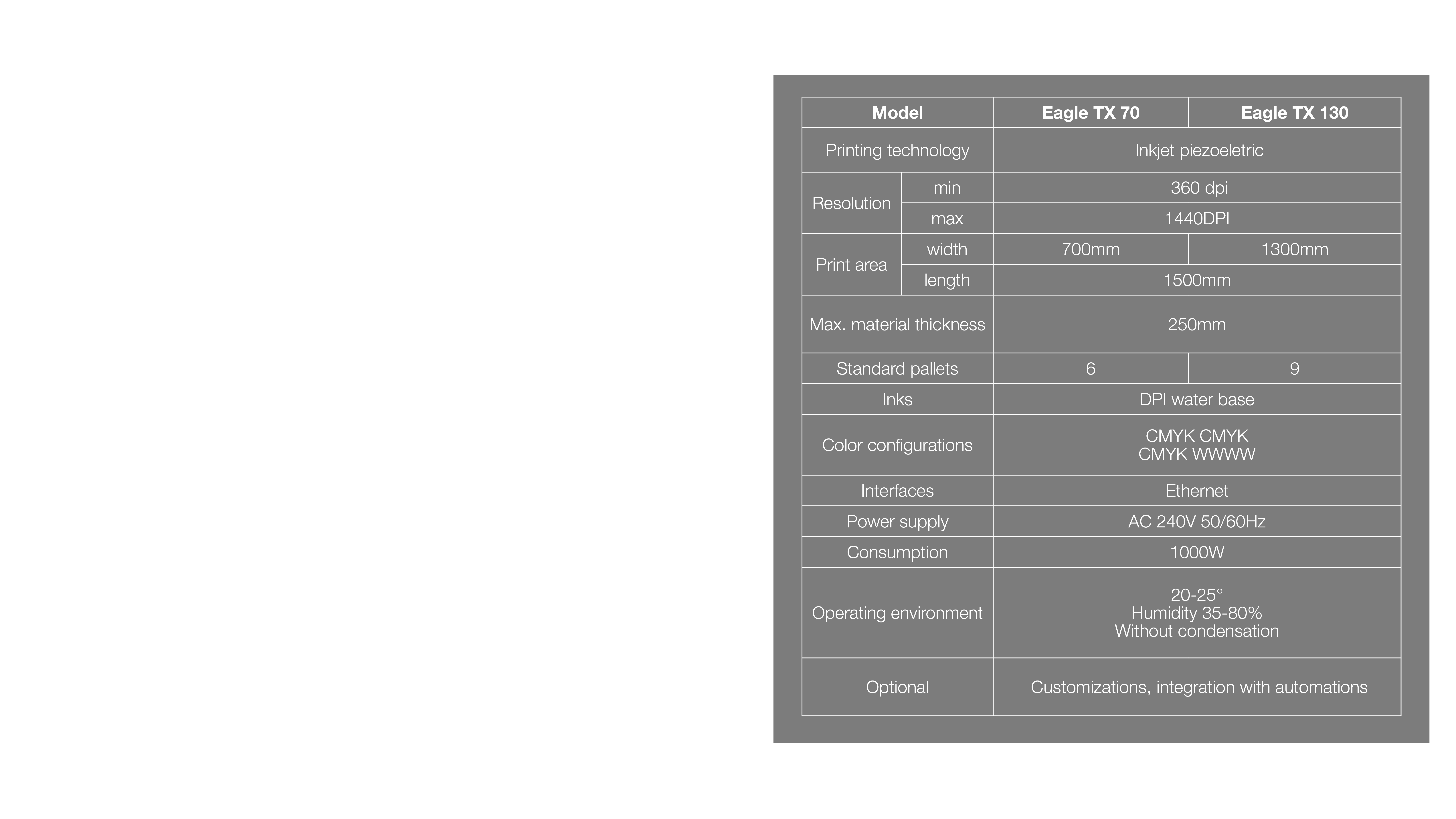

Water based inks

With water based inks you can print on fabric for clothing, fabric for gadgets, fabric for furniture, towels, caps, canvases and more.

After printing dry with a thermo-press or an oven to permanently fix the ink to the fabric.Thanks to the white ink you can print also on black or dark fabric.

Key points:

Thickness up to 250mm

New generation printheads

More powerfull water cooled drying lamp

Wing design of our own design

Pressurized ink system with recirculation

Dedicated software RIP: WhiteRIP

Key points:

Thickness

The print thickness of 250mm, extensible up to 450mm on request, allow Eagle printers to print very bulky materials.

The printer is able to detect the object height avoiding collision that will damage the print head.

Key points:

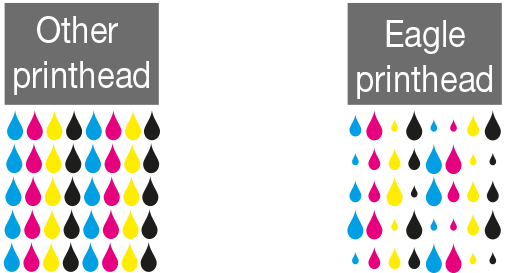

New generation print heads

The new print heads have a better performance, they last longer, thanks to the mirror treatment to prevent the deposit of color and clogging of the print nozzles.

Moreover the new print heads can generate variable dots significantly improving the performance especially in gradients.

Key points:

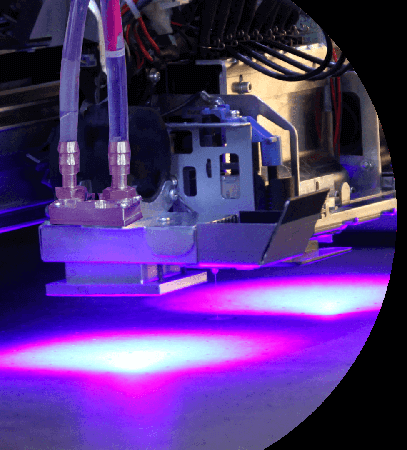

More powerfull water cooled drying lamp

Our UV Led printers are equipped with two UV Led lamps to dry the ink.

Thanks to this technology the material is ready to use immediately after the print, without other processing. The new UV Led lamps on Eagle UV 70 are further improved, adjustable in power and water cooled.

The Hybrid printers instead are equipped with a single halogen lamp adjustable in power allowing to adapt the heat to the support.

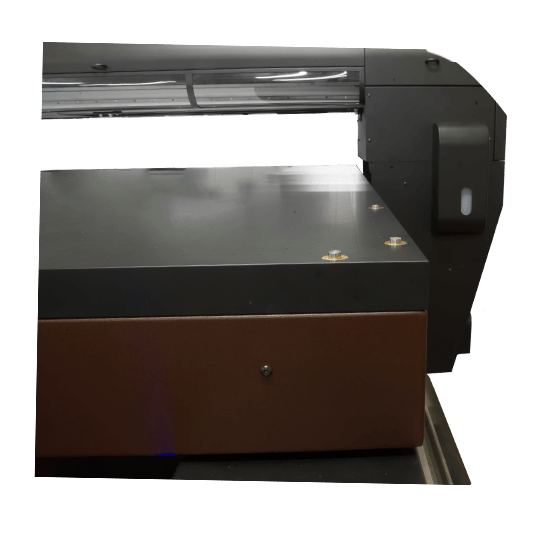

Key points:

Wing design

The innovative wing design of Eagle allow easy access to the print table even during the print stage. This allow to reload the print table while the printer is running and load materials larger than the print table.

Key points:

Pressurized ink system with recirculation

Eagle printers use a bottle ink system under pressure and with constant recirculation of white inks. This avoid the formation of clots and the formation of bubbles in the circuit reducing down time and maintenance costs.

Key points:

Dedicated software RIP: WhiteRIP

All Eagle printers are provided with a dedicated professional RIP software WhiteRIP developed in partnership with EvNetwork with specific function to increase the production and reduce the inks consumption among which:

Inline printing

Print with template

Auto generation of white ink

Print with 3D effect

Print simultaneously 3 layer color/white/color (glass mode).

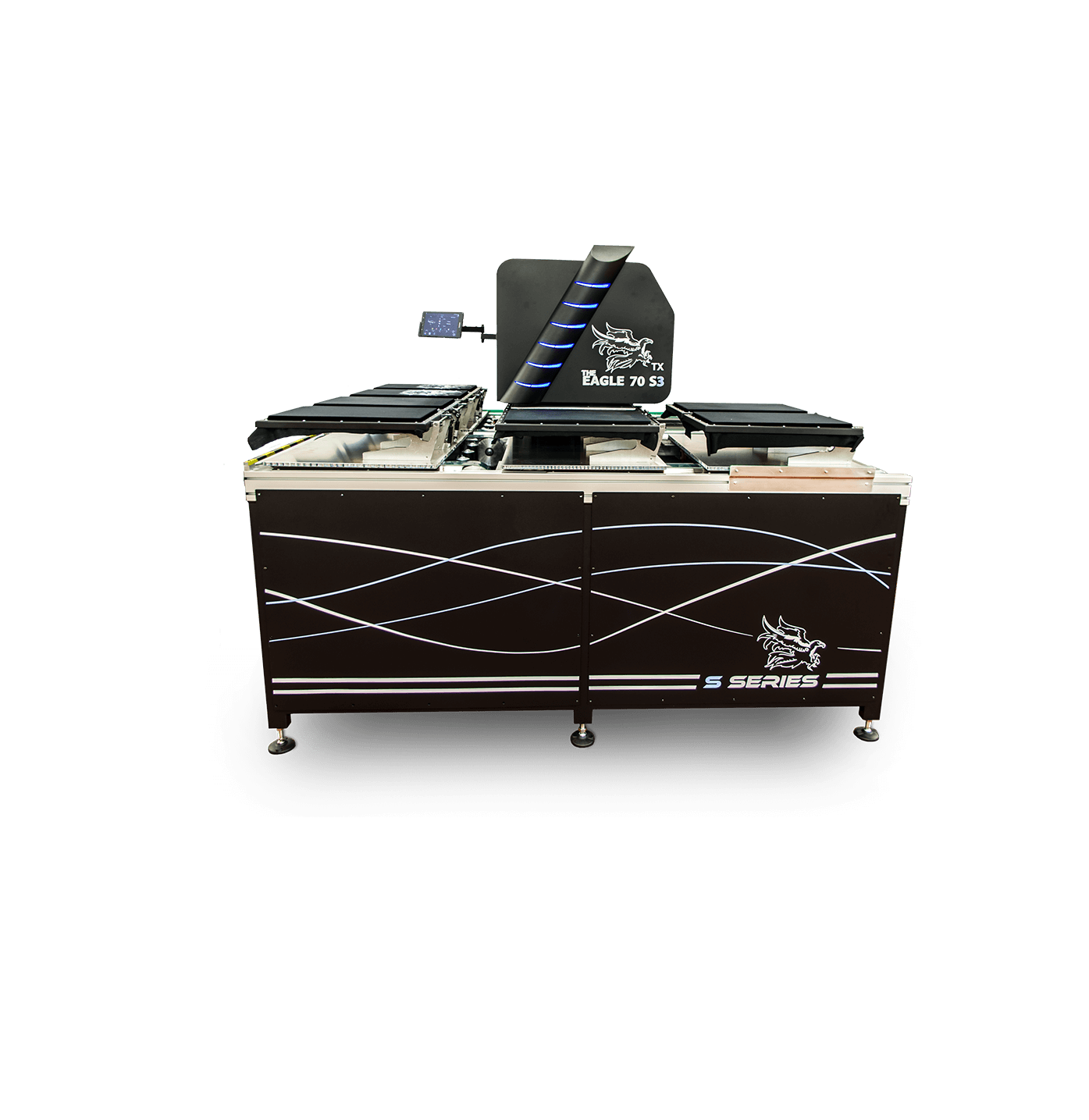

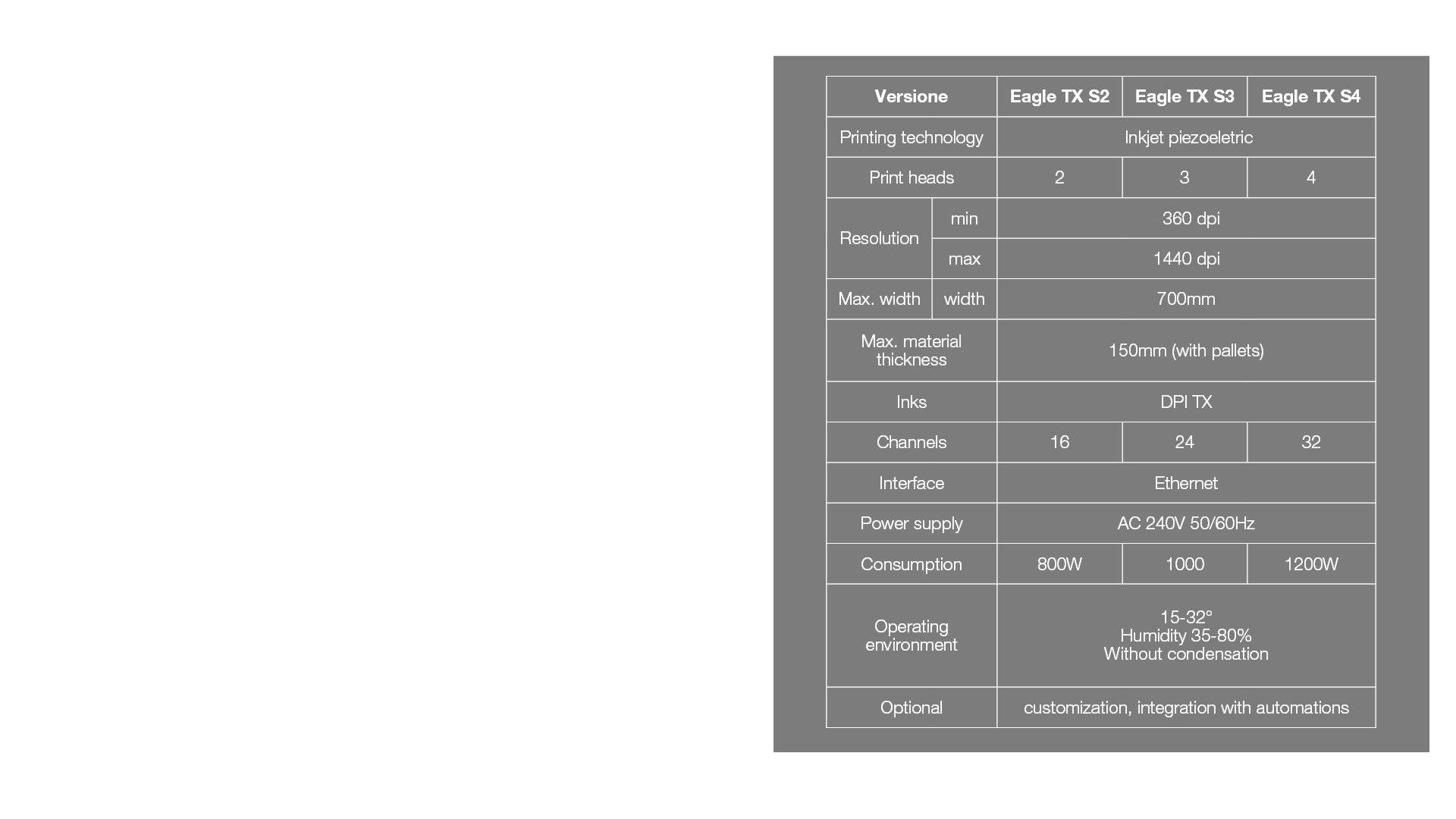

New Eagle TX S

Eagle TX S is equipped with the new multihead technology developed by Ser.Tec. with which is possible to manage multiple print head.

Eagle TX S is available with 2,3 or 4 heads depending on production needs.

The pallet transports system allow to easily integrate the printer with an automatic return system (optional) that allows a single operator to load and unload tables in one station reducing the required workforce and increasing production up to 120 shirt/ h on dark garments.

In addition, Eagle TX S can be controlled from a remote tablet with the ability to print without computer prior work

Optional

The Eagle printers can be equipped with optional that extent their versatility and functionality:

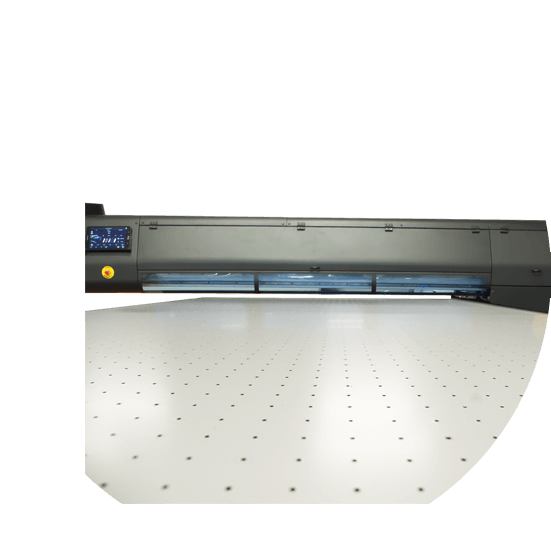

Vacuum and blowing table

Square

Circular object kit

Customizable print length

Customizations

Optional:

Vacuum and blowing table

Eagle printers can be equipped with vacuum table that help keep object in place and ovoid movements during the print.

To help move heavy objects is possible to mount a blowing system that allow you to float the materials.

Optional:

Square

The square is useful to pre-register the material.

The square is retractable so it does not clutter during the print phase or during the loading operations.

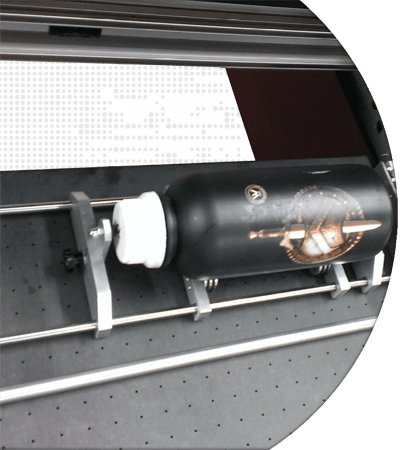

Optional:

Circular object Kit

The circular object Kit allow to easily print on circular items. The kit can be mounted and unmounted in a very short time allowing to switch production type quickly.

Optional:

Customizable print length

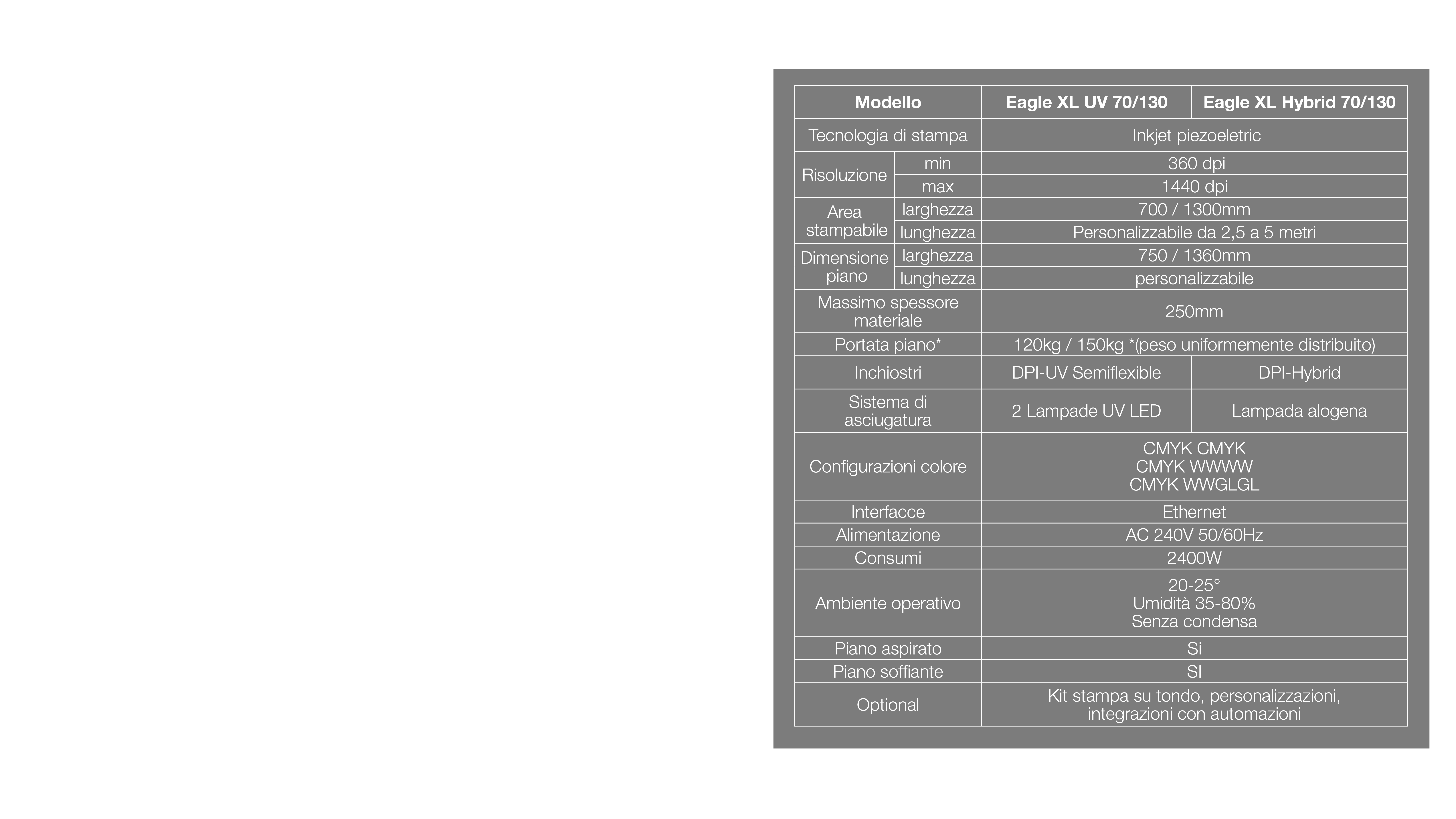

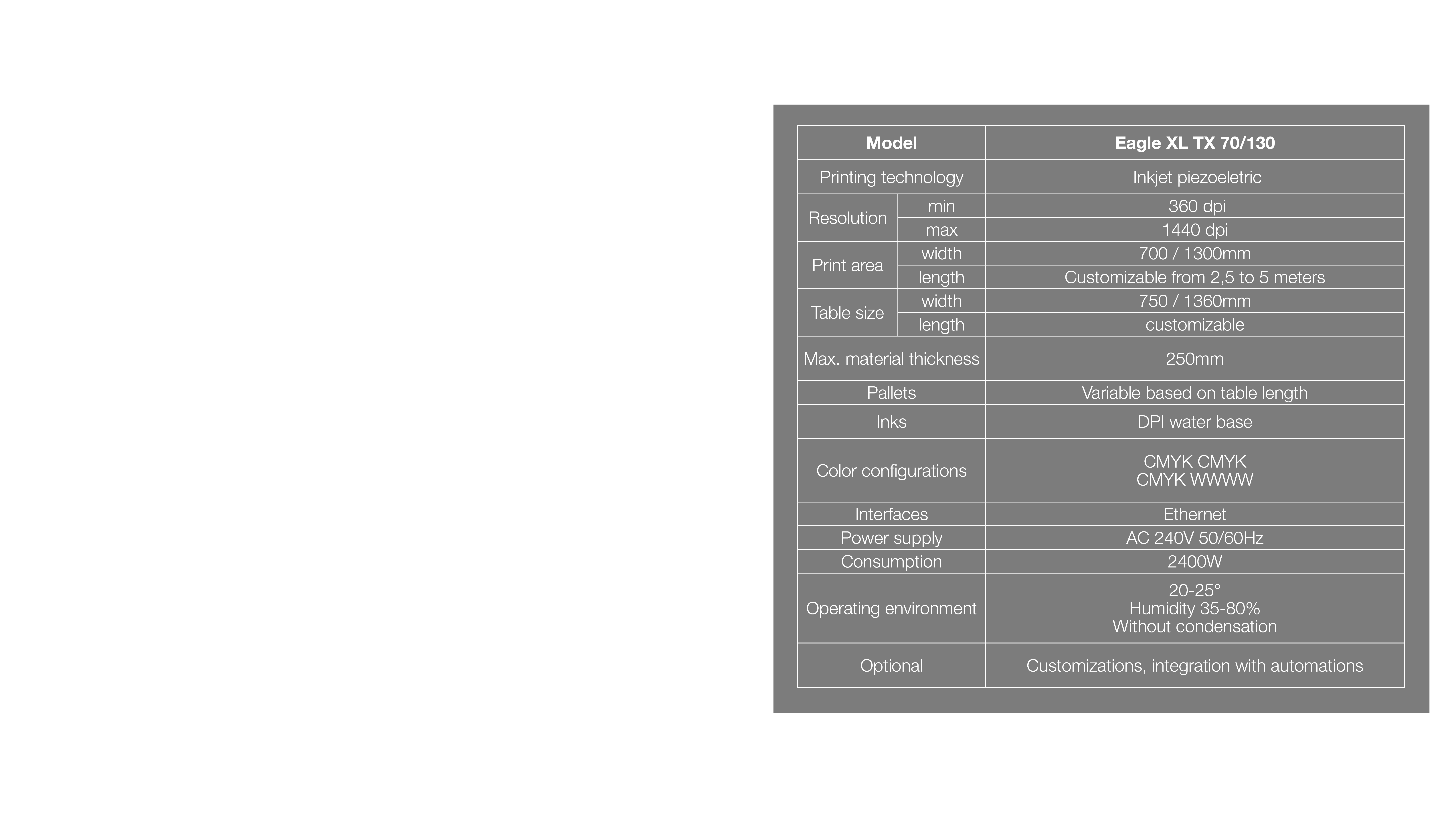

The print length of the Eagle XL is customizable, starting from 2,5 meters.

You can choose the best size for your needs.

Optional:

Customization

Eagle printers can be customizes to meet specific manufacturing needs, including an automatic floor loading and unloading system, increased vacuum systems, special printing tables, etc...

the

eagle

series