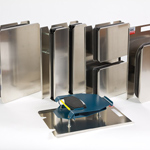

DTG presents the new M2 Printer

DTG Digital has been at the forefront in the market for direct printing on fabrics, introducing technologies that have improved the quality standards and imposing itself as an industry standard.

Whatever was the type of project, for each machine designed by DTG, productivity has always been kept in mind. It would be fair to say that this concept has always been present in all stages of development of the DTG series and was also a key concept for the new M-series that was presented during the show FESPA Digital this year in Hamburg.

This new line offers unrivaled speed and inkjet settings controlled by a completely new firmware, built specifically for decorating fabrics. You can, for example, print the blank with the larger droplets at high resolution, with un'incremento productivity by about 3 times, than any other printer on the market! The firmware also allows you to reach a wider gamut: the profiles were created specifically for DTG, instead of being merely a rehash of those provided by the manufacturer of the print engine. Further development of the firmware also improved the quality of low-resolution printing, eliminating any bandature. The correction formula devised by DTG acknowledges the edges marked usually seen between the steps and compensates with a dot placement of an intelligent and controlled flow of ink, so as to remove burrs, resulting in sharper prints. Even with bidirectional printing, the replacement of the system reduces and often eliminates dot the differences of tone-to-lock.

The piezo head coated in Teflon, widely recognized as the best print engine, with 8 channels and 180 nozzles per channel, is an integral part of the impressive specifications of the new system DTG M series With this head, you can print images of high quality, 1440dpi for example, at a faster rate, while maintaining high quality. This also means that when the prints are needed faster, you will not have to settle for more than 600 prints at 720 dpi. It will instead be able to produce higher quality prints, which were first devoted solely to slower processes.

It was also revised the ink consumption by implementing a new WIMS (White Ink Management System), which incorporates a peristaltic pump pressurized to 1.2 psi and a new system for the mixing of colors. This system not only allows the separation of white (without manual agitation), but maintains a constant pressure to both white and CMYK inks, eliminating air bubbles in an efficient manner, delivering a perfect level of ink at the head of printing and effectively minimizing the amount of ink wasted. The new version of the WIMS system also uses brushless motors, extending the life of the engine.

Despite the level of development that has been reached for the construction of this series, the capital outlay was competitively low, with savings of up to 40% compared to some of the other machines in the market. Adding the cost of ink lower, higher production, connected by a network of support and service second to none, you have the perfect combination for your business.

In order to prove this true revolution in the world of direct digital printing on fabric contact our offices at: info@dpidgprinting.com

Gallery

Click on the icons for a higher resolution pic

Search