The New Rotopress: Revolution in the Industry!

Increase Productivity with the New Rotopress: Revolutionizing the Industry!

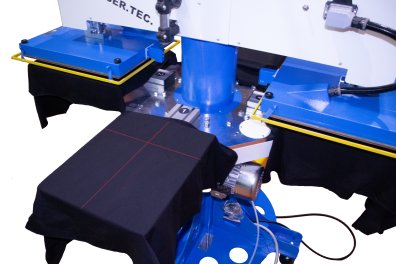

In an era where DTF (Direct to Film) technology is widely spread, an innovative solution is emerging that is revolutionizing the industry: the Rotopress. This press, unique in its kind, promises to reduce pressing times by 50% compared to traditional double-plate models.

The secret of the Rotopress lies in its advanced automatic rotation system. Thanks to four rotating tables, it is possible to manage the entire pressing process with a single operator, optimizing time and resources. The mechanism allows loading and unloading a T-shirt every 7 seconds, completely revolutionizing the workflow.

This is possible thanks to the reduction of transfer times: while a standard press takes 14 seconds per cycle, with a Rotopress, this time is halved, allowing greater production efficiency.

The option to work with two operators also allows simultaneously executing two different jobs, further increasing productivity. The Rotopress is comparable to a carousel in its operation: smooth, efficient, and designed to maximize output in terms of quality and speed.

With this innovation, the Rotopress positions itself as a must-have for companies looking to optimize their fabric printing processes, promising to be a turning point in the industry.

Have questions? We are happy to provide consultations via phone, email, or at our headquarters in Treviso!

Search