Applications:

- Workwear

- Sportswear

- Adhesives

- Badge

- Bags and purses

- Caps

- On demand decorations

- Appliance

- Advertising displays

- Floor Graphics

- Gadgets

- Religious objects

- Packaging and prototypes

- Panels and keyboards

- Advertising panels

- Posters

- Color proofing

- Stores and shops

- Backlighted

- Artistic reproductions

- Photographic reproductions

- Signage

- Soft signage

- Sport and work

- Sticker

- Outdoor banners

- Indoor banners

- Glass and windows

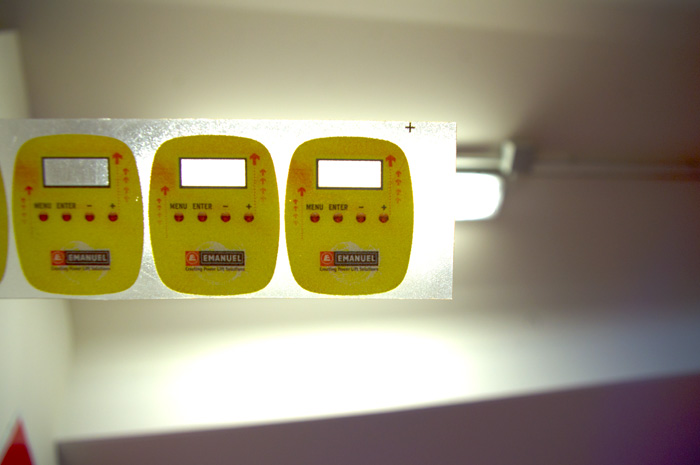

Panels and keyboards

What is UV printing

With UV printing is defined a kind of printing where the ink dry through the exposure to UV rays(Ultra Violet) almost istantly. The UV inks contain some elements called photo-initiators or photo-ionization.

Thoose elements, exposed to UV light of the lamps activate a reaction of the ink called polymerization or crosslinking.

The molecules of the ink tend to group to defined patterns, while the liquid component evaporates, always under the effect of UV light. This process is also called UV Curing, where curing stands for polymerization.

Because of the ink deposit on the material's surface and not inside it ( like ecosolvent ink ), with UV ink it's possible to print on a large range of materials and have beautiful effects of polishing or embossing.

This characteristic makes the UV printind ideal to print on smooth or special surfaces not printable with other technology. The classic application is the realization of panels and membrane keyboard.

Membrane keyboard and panels

With the possibility of printing white ink on polycarbonate and other plastic materials, DPI plotters are the ideal solution for prototyping and the realization of membrane keyboards. Each keyboard has a graphic specifically studied according to customer needs and the type of interface.

Being able to realize a prototype faithful to the final product allow both to avaluate and correct the product in phase of study and to present to the customer product same as the one he will receive once the work is finished.

Thanks to DPI printers it's also possible to realize small lots of membrane keybord without all the screen printing process.

Mirror printing under the material

The realization of membrane keywords happens in most cases printing the graphics mirrored on the back of the material. In this way the wear of fingers touch don't affect the print but only the material. In this case you need to print first the mirrored graphic and then the necessary white layers.

Search