The new products presented in 2021 by Ser.Tec.

2021 is ending and it is time for the Ser.Tec group to look to the past. This year, despite the challenges posed by the pandemic, we presented new printers with new technologies and equipment such as the new Digiscreen S equipped with Ricoh Gen 5 heads or the DTF printing lines. It was also a positive year for the screen printing sector where we renewed the new line of linear screen printing machines.

Below is a brief summary of our main products launched in 2021

Digiscreen S

Presented at Visiva 2021 Digiscreen S is the new solution to integrate digital printing in screen printing carousels.

Equipped with Ricoh Gen 5 industrial print heads to ensure high quality and productivity, Digiscreen S is compatible with any type of screen printing carousel.

DTF technology

2021 saw the emergence of DTF technology with Ser.Tec. which launched printing solutions from short runs to industrial production.

We start with DTF 400, a machine that can print films in A3 format or in reels up to 30cm.

DTF 300, on the other hand, is equipped with a more performing printing station, with 2 print heads for higher production volumes on 30cm reel film.

Finally, DTF 600 is the solution for those who need high production volumes. This line is in fact equipped with two heads for printing film in reels up to 60cm ensuring excellent quality and at the same time high speed.

For all lines, the presence of an oven with duster and rewinder makes it possible to automate the production process.

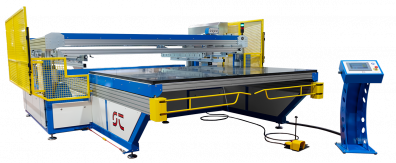

New linear screen printing machines

During 2021, SerTec renewed its line of linear screen printing machines by integrating innovative solutions to the mechanical, electronic and software parts that increase the versatility of the machines and make them compatible with the Industry 4.0 standard.

Eagle Hybrid printing line

The Hybrid printing line is designed for materials such as ceramic, metal and glass. It is made up of "The Eagle 70 Hybrid" industrial printer with carpet loading and pre-heaters, mounted in line with the "FT Radiant" radiant panel oven, equipped with a metal mesh belt that guarantees greater flow rate and less wear especially with materials such as ceramics and metals.

The modular construction of the "Hybrid" line allows it to be inserted into existing production lines and to customize it according to the materials and production needs of the customer.

Eagle 130 custom roll to roll

Il gruppo Ser.Tec. ha realizzato diverse stampanti customizzate, in questo caso una Eagle roll to roll.

Il gruppo Ser.Tec. ha realizzato diverse stampanti customizzate, in questo caso una Eagle roll to roll.

La stazione di stampa è costituita da una Eagle Hybrid 70 equipaggiata con speciali inchiostri reattivi richiesti dal cliente, mentre a lato trovano posto i supporti per lo svolgimento e riavvolgimento dei nastri in bobina.

La stampante è infatti dotata di supporto di alimentazione per le bobine con sistemi di tensionamento e stazione di riavvolgimento finale, rendendola completamente automatica nel suo funzionamento.

Un preciso sistema di rulli si occupa dell'avanzamento dei nastri mentre le guide sul piano di stampa ne assicurano la posizione.

Grazie al software RIP di stampa WhiteRIP e alla sua funzione Template, il posizionamento delle immagini sui 5 nastri è semplice e rapido, assicurando cosi un risparmio di tempo e materiale.

Eagle 130 Hybrid custom table

Many custom Eagle models made this year included a modified table for various needs. This particular model of Eagle HY 70 has a part of the table that can go down to add another 60cm to the standard 25cm opening. The top can be completely raised to take advantage of the entire printing area of 130x150cm for materials with a thickness of less than 25cm.

The Ser.Tec. group gives you an appointment for 2022 during which important news in the digital printing sector will be presented.

Search